When Jeremiah Chamberlain and his wife, Harriet, started their 3D-printing business in March last year, tariffs weren’t high on their list of challenges to prepare for.

“We didn’t expect to have this type of panic arise,” said Chamberlain, the owner-operator of Corvidae Creations in Hammond, Louisiana. But in the months since President Donald Trump took office and kicked off a freewheeling global trade war, Chamberlain has spent a few thousand dollars more on 3D printers from China. Chinese-made goods currently face a U.S. tariff rate of at least 30%, down temporarily from 145% just weeks ago.

Chamberlain has already ditched a Chinese supplier after it raised the cost of bulk filament orders from $14.99 to $17.99 per roll. Leaning only on American and Canadian filament vendors has actually saved money, Chamberlain said, allowing him to lower some prices — and the Chinese firms wound up walking back some of their own price hikes anyway. But he’s had to do without certain color options since making the switch.

“The whole point of it, when we went into the toy production, was to make a durable, affordable toy for families and children,” he said, referring to his lineup of dragons, possums and dinosaurs. “Nothing’s going to make me raise prices unless it’s a matter of me having to shut the business down totally.”

The company is one of many across the country promising not to raise prices on customers despite Trump’s import taxes.

Some large corporations, like Home Depot, have ruled out price hikes for now, saying they have the flexibility to adapt. Others, including Nike and Walmart, plan to raise some prices, while Target this week called doing so a “very last resort.” Many other businesses are trying to hold firm, too, as consumers grow more pessimistic and hunt harder for bargains. The online clothing and home goods seller Quince recently told customers it’s committed to keeping prices steady “for as long as we can,” despite sourcing many items from China.

A White House spokesperson didn’t respond to a request for comment.

Main Street shops and other small operators say they feel boxed in by the trade war. Some have been trying in the meantime to leverage “anti-tariff” promotions and other sales gambits. Many see the ever-changing U.S. duties as an existential threat that they’ll need customers’ help to survive. In a Main Street Alliance survey of small-business owners this spring, 81.5% said they’d have to raise prices to handle tariffs, and 31.5% said they’d lay off workers.

“When you go back and forth from 10% to 140% to 30%, and now you’ve got a blanket ambient tariff regime, it is impossible to plan,” said Richard Trent, executive director of the advocacy group, which represents over 30,000 small businesses. “Small-business owners are operating on such thin margins. The least that we could do is give them a modicum of stability.”

Some entrepreneurs see their duty to customers much the same way.

“I won’t be raising prices,” said Carla Minervini, who runs All Fired Up, a pottery studio in Pawleys Island, South Carolina. “I cannot do that to my community.”

Like Chamberlain, Minervini is doing her best to adapt. She has reassessed her product assortment and is working to sub in smaller versions of certain pieces or find alternatives in different shapes.

She also stocked up on materials earlier this year, anticipating price increases from tariffs. Her main supplier — which is based in the U.S. but imports items from China — announced a 7.25% across-the-board price hike starting in June, she said. Another supplier flagged coming increases, too, but hasn’t indicated when or by how much.

I would sell everything off and close my business and make a new life for myself before I would increase my prices.

Carla Minervini, owner of All Fired Up pottery studio, Pawleys Island, S.C.

Minervini is unwavering, though. “I would sell everything off and close my business and make a new life for myself before I would increase my prices,” she said.

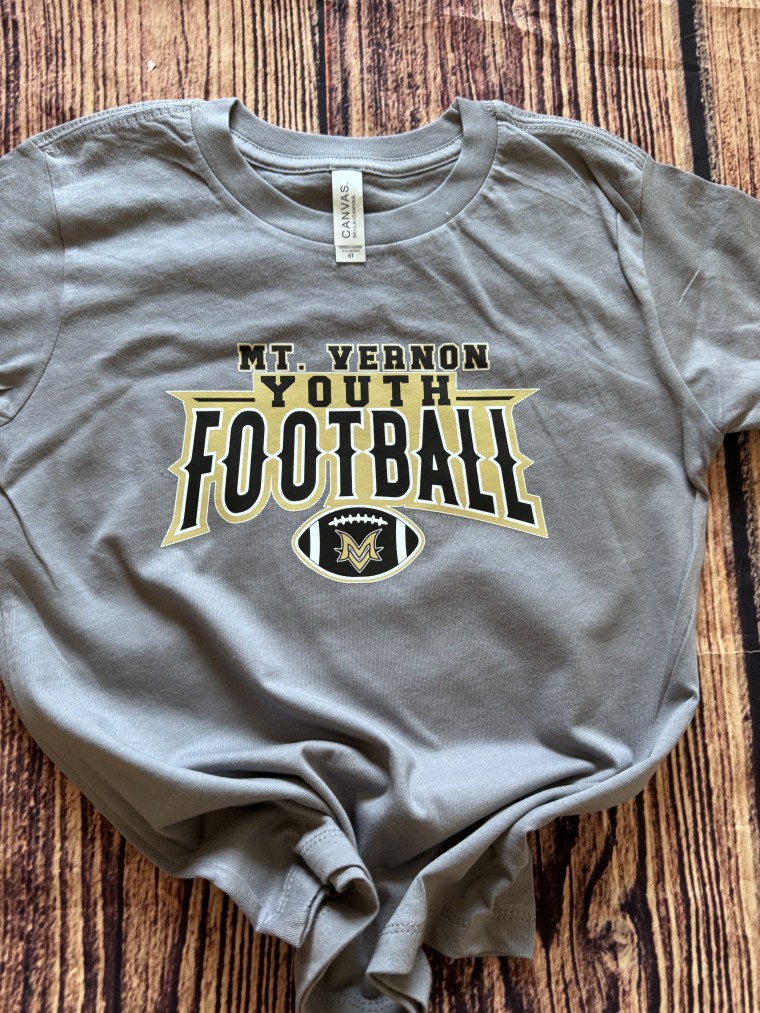

For Dan Jones and his wife, Ashley, tariffs have meant fewer hands helping with Jeans Day Apparel, the clothing company they co-own in McCordsville, Indiana. The business — currently a side gig alongside the Joneses’ full-time jobs — sells custom tees, pants and accessories for schools, sports teams and events.

Jones said costs for supplies like ink, printing paper and clothes have gone up 3% on average since March. But rather than raise prices, he and Ashley let go of the handful of high schoolers who typically help out part time to make apparel for $12 to $15 an hour.

“We have to be able to cut costs somewhere, and labor is the easiest place,” he said. The trims mean more work for Dan and Ashley, eating into their family time and pushing back plans to move the company out of the garage and into a storefront.

“We just don’t know what the future looks like,” he said. “It’s the unknown that’s very scary.”

Amy Grows, a retired U.S. Forest Service forestry technician and owner of Camas Creek Soap Company in Sagle, Idaho, doesn’t want to impose across-the-board price hikes.

“I don’t think I need to do that to people,” she said. “It’s just soap.”

To keep her bars at about $6 apiece for as long as she can, Grows joined the wave of businesses and consumers that stockpiled goods earlier this year, hoping to get ahead of tariffs. But her suppliers have already warned of potential price increases, so she plans to reduce the varieties of soap she makes by around 25%, focusing on top-selling items. She’s also swapping out palm and olive oils for cheaper alternatives wherever she can.

“I’m trying to make a little money for me and give people a good product that they can afford,” Grows said.

Last month, all four of Amelia Morgan’s U.S. suppliers announced 20% price hikes on the plaques, trophies and other components her awards business depends on. Recognitions Awards and More, based in Aviston, Illinois, can’t eat the added costs of those materials for long, Morgan said.

She has held off on raising her own prices for weeks but expects she’ll need to finally give in sometime next month.

“We’ve got people who depend on us to be able to pay the mortgage, be able to buy groceries, make car payments,” Morgan said of the six workers she and her husband employ. “We have to make sure that we stay profitable.”

Latest World Breaking News Online News Portal

Latest World Breaking News Online News Portal