NEWYou can now listen to Fox News articles!

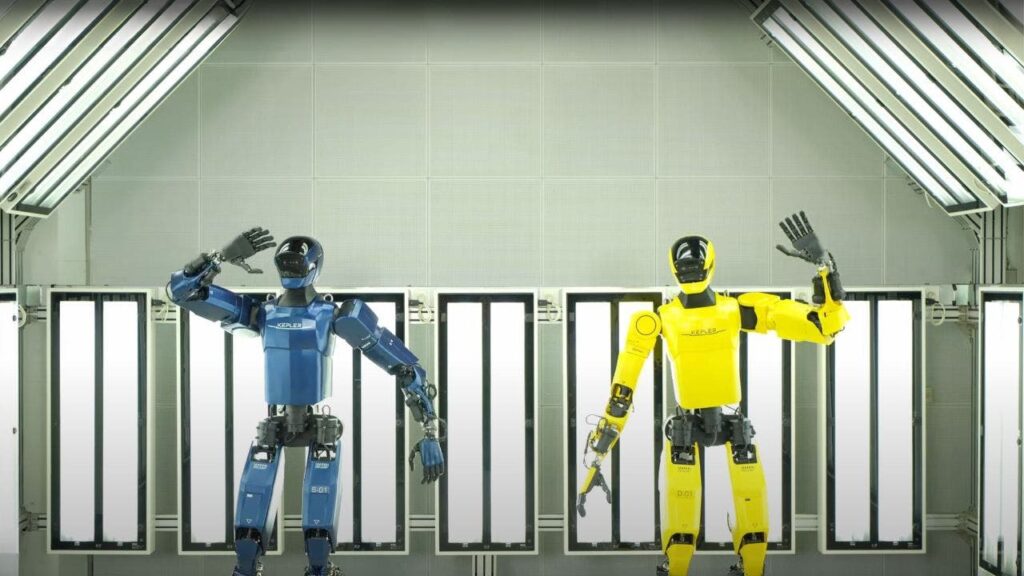

Kepler Robotics has officially introduced its Forerunner K2 “Bumblebee” humanoid robot at the SAIC-GM automotive plant in Shanghai, marking a significant moment in the real-world deployment of advanced robotics. In a recently released video, the K2 is seen moving confidently through the plant, performing detailed quality checks, and handling assembly operations that demand both strength and precision. This debut signals the beginning of scenario-based testing for Kepler’s humanoid robots across a variety of industrial settings, where their capabilities can be evaluated in live production environments.

Sign up for my FREE CyberGuy Report

Get my best tech tips, urgent security alerts, and exclusive deals delivered straight to your inbox. Plus, you’ll get instant access to my Ultimate Scam Survival Guide — free when you join.

Humanoid robots at the SAIC-GM automotive plant in Shanghai (Kepler Robotics)

How Kepler’s K2 “Bumblebee” is changing automotive manufacturing

The K2 “Bumblebee” robot is built for the demands of modern factories. At SAIC-GM, it has already demonstrated its ability to perform intricate inspections, navigate complex factory layouts, and manage heavy automotive components with impressive autonomy. The robot can load stamped parts, manipulate mechanical fixtures, and adapt to new tasks using a combination of imitation and reinforcement learning. Its presence in the factory highlights a shift toward smarter, more efficient production lines, where robots and humans work side by side to achieve higher standards of quality and safety.

Forerunner K2 “Bumblebee” humanoid robot at the SAIC-GM automotive plant. (Kepler Robotics)

HUMANOID ROBOT MALFUNCTIONS AND SPARKS VIRAL PANIC

Mechanical and AI advancements in the Forerunner K2

Kepler’s Forerunner K2 is a notable step up from its predecessor, the K1, thanks to extensive improvements in both hardware and software. The K2 features a reinforced limb structure for greater durability and easier maintenance, tactile manipulators with an impressive 11 degrees of freedom per hand, and flexible fingertip sensors that boost its dexterity. Its integrated battery allows for up to eight hours of continuous operation, supporting the long shifts required in industrial settings.

On the intelligence side, the K2 leverages a cloud-based cognitive system that enables it to learn new tasks quickly and coordinate its movements with full-body awareness. Enhanced perception, task planning, and improved human-robot interaction algorithms allow the K2 to operate independently while collaborating smoothly with human coworkers.

Forerunner K2 “Bumblebee” humanoid robot at the SAIC-GM automotive plant. (Kepler Robotics)

AI HUMANOID ROBOT IS CHANGING THE WAY YOU BUY CARS AT DEALERSHIPS

Kepler’s K2 and the future of humanoid robots in industry

Kepler’s ambitions for its humanoid robots extend far beyond automotive manufacturing. The company envisions these robots playing active roles in education, research, security, logistics, and hazardous outdoor operations. In classrooms, the K2 can support interactive learning and real-time coaching, while in research labs, it can help with data gathering and experimental tasks.

For security applications, the robot’s advanced sensors enable it to patrol complex areas, detect emergencies, and assist in rescue operations. In logistics, the K2 is designed to automate goods handling and warehouse management, increasing both accuracy and efficiency.

Its robust design, waterproofing, and resistance to extreme temperatures make it suitable for challenging environments, including areas with radiation or explosive hazards. The K2’s autonomous navigation and real-time monitoring capabilities help reduce risks and boost productivity, especially in high-risk conditions.

Forerunner K2 “Bumblebee” humanoid robot at the SAIC-GM automotive plant. (Kepler Robotics)

CHINESE HUMANOID ROBOT WITH EAGLE EYE VISION AND POWERFUL AI

What Sets the K2 Apart

The Forerunner K2 stands out for its precision, endurance, and adaptability. With advanced manipulators and flexible sensors, the robot can handle delicate and complex tasks that require a human-like touch. Its eight-hour battery life supports continuous operation during long industrial shifts, and its learning algorithms enable it to adapt to new tasks and environments with minimal retraining.

Kepler also emphasizes the cost efficiency of the K2, stating that it can match or exceed the workload of multiple human workers in certain scenarios, making it a practical addition to high-demand workplaces. The company has set the base price for the Forerunner K2 at around $30,000, positioning it as an accessible option for manufacturers seeking to boost productivity and efficiency with intelligent robotics.

Forerunner K2 “Bumblebee” humanoid robot at the SAIC-GM automotive plant. (Kepler Robotics)

Addressing concerns about job displacement

The introduction of advanced humanoid robots like Kepler’s K2 naturally raises questions about the future of human employment in manufacturing and other industries. It’s true that automation and robotics have the potential to change the way work is organized on the factory floor. Some worry that robots could replace jobs traditionally held by people, especially in roles that involve repetitive or physically demanding tasks.

However, experts and industry leaders point out that the story is more nuanced. While certain jobs may be automated, new opportunities often emerge alongside technological advancements. For example, the rise of robotics is expected to create roles in robot maintenance, programming, AI training, and oversight, jobs that require different skills but are essential to supporting and managing these new systems. Many analysts believe that robots like the K2 are likely to complement human workers by taking over monotonous or hazardous duties, which allows people to focus on more complex, creative, or supervisory tasks.

Collaborative robots, or “cobots,” are specifically designed to work alongside humans, enhancing productivity and safety rather than simply replacing labor. This collaborative approach can lead to new forms of teamwork and innovation on the factory floor, making work environments safer and more efficient. Ultimately, the integration of humanoid robots is expected to shift the workforce rather than eliminate it, opening up new possibilities for both businesses and employees as they adapt to a more automated future.

SUBSCRIBE TO KURT’S YOUTUBE CHANNEL FOR QUICK VIDEO TIPS ON HOW TO WORK ALL OF YOUR TECH DEVICES

Forerunner K2 “Bumblebee” humanoid robot at the SAIC-GM automotive plant. (Kepler Robotics)

Kurt’s key takeaways

Kepler’s K2 humanoid robot making its debut at SAIC-GM is a big step forward for robotics in real-world workplaces. Watching these robots take on challenging tasks alongside people shows just how much potential there is for collaboration between humans and machines. As more companies explore what humanoid robots can do, it’s going to be fascinating to see how these partnerships shape the future of work and industry.

Despite what experts and industry leaders say, does it concern you that as robots like Kepler’s K2 take on more tasks, human workers will be replaced? Let us know by writing us at Cyberguy.com/Contact.

For more of my tech tips & security alerts, subscribe to my free CyberGuy Report Newsletter by heading to Cyberguy.com/Newsletter.

Ask Kurt a question or let us know what stories you’d like us to cover.

Follow Kurt on his social channels

Answers to the most asked CyberGuy questions:

New from Kurt:

Copyright 2025 CyberGuy.com. All rights reserved.

Latest World Breaking News Online News Portal

Latest World Breaking News Online News Portal